*0.008 inch fine bristles: Diameter data from the Shenzhen Silver Star Intelligent Technology Co., Ltd. lab. 10 individual bristles were measured using a micrometer with a precision of 0.0004 inch. Results indicate a bristle diameter of 0.008 inch, with a variation of 土0.002 inch.

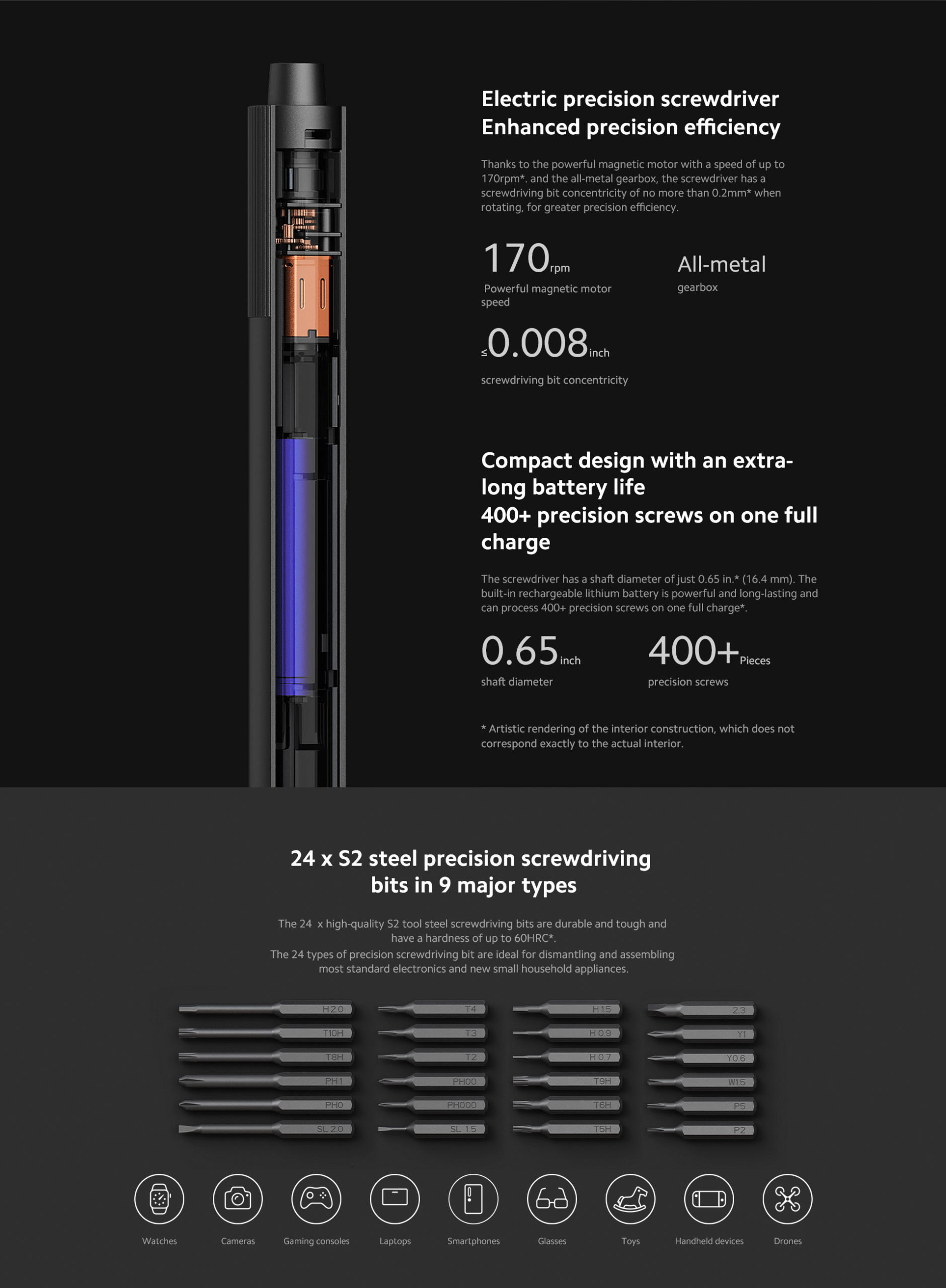

* Spindle runout (i.e. precision bit concentricity) test method: A standard test rod is inserted into the output shaft. A laser diameter gauge is used to measure the runout at a distance of 1 inch from the end surface of the output shaft.

* The dimensions stated may vary or be inaccurate due to different measurement conditions.

* Screwing test method: The device is fully charged until the white lamp is illuminated. The ST2 x 0.2 inch self-tapping screw is then driven into the pine board until the battery runs out.

* Hardness varies by ±2HRC. Screwdriving bit hardness tests were conducted by the National Light Industry Tool Hardware Quality Supervision & Testing Station, Shanghai. Report No.: G20200215.

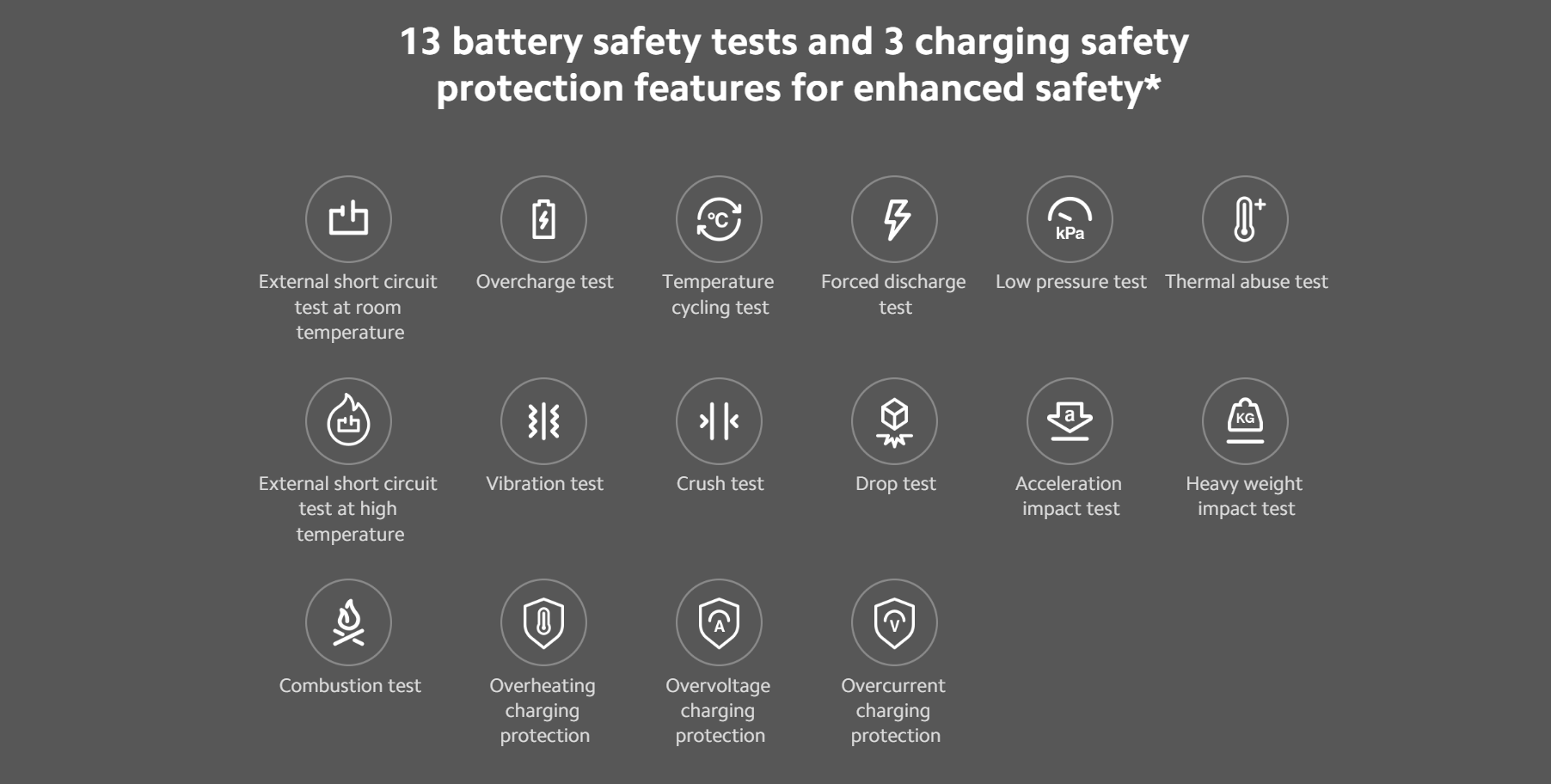

* Torque at level I varies by ±0.03Nm and torque at level II varies by ±0.08Nm. Torque test method: The fully charged device is run without load for 2 minutes and a torque tester is then used to measure the torque at levels I and II.* The battery was tested by the Southern Testing Company of the China Certification & Inspection Group. Report No.: SET2019-08673. The battery protection tests were conducted by Precise Testing & Certification (Guangdong) Co., Ltd.; Report No.: PTC20032303001S-GB01.

* Unless otherwise indicated, all data referred to on this page is from the HOTO Laboratory. Data may vary or be inaccurate due to differences in the objective environment and other factors.